By John House

Editor’s note: The first installment of John House’s adventure retrieving a 1959 Cessna 175 from Minneapolis can be found in the October 2020 EAA chapter 1541 newsletter, which is available here.

We pick up the story on the morning of the departure from Minnesota to California:

We pick up the story on the morning of the departure from Minnesota to California:

I filed for Anoka County, MN (KANE) to Mobridge, SD (KMBG) for the first leg.

We rolled the airplane out of the hangar just as the sun was coming up – sort of. It was overcast with lite winds out of the east at about 6 knots and mid-40’s temps. I loaded up my gear, did a preflight, put on my survival vest and climbed in. I pushed in the mixture, gave it a couple squirts of prime, grabbed the huge white knob on the throttle and pulled the starter. It roared to life but with the same roughness as the day before. I leaned it out.

Since the tower didn’t open for another hour, I picked my own runway and off I taxied to runway 09. I did a very thorough runup and when satisfied nothing was amiss, I announced my intentions on both the CTAF and tower frequencies. I had enriched the mixture for the runup and left it there for departure. I planned to climb to 8,500 but due to the overcast I never got there. I ended up staying at 4,500 (3,000 agl) with some skirting around low clouds a bit. While certainly not a deal breaker, at that altitude I was below radar coverage and I lost Minneapolis Center after about 45 minutes. I was on my own from here on out, but the terrain is flat and there are lots of airports along the first half of the leg. The further west I flew the greater the distance between airports, towns and for that matter – anything.

Since the tower didn’t open for another hour, I picked my own runway and off I taxied to runway 09. I did a very thorough runup and when satisfied nothing was amiss, I announced my intentions on both the CTAF and tower frequencies. I had enriched the mixture for the runup and left it there for departure. I planned to climb to 8,500 but due to the overcast I never got there. I ended up staying at 4,500 (3,000 agl) with some skirting around low clouds a bit. While certainly not a deal breaker, at that altitude I was below radar coverage and I lost Minneapolis Center after about 45 minutes. I was on my own from here on out, but the terrain is flat and there are lots of airports along the first half of the leg. The further west I flew the greater the distance between airports, towns and for that matter – anything.

Minnesota is called “The Land of Ten Thousand Lakes”, and there’s no doubt in my mind it’s true. Quite a change from here in the West. I believe California is named the Golden State not for the precious metal found here but rather for the color of the landscape during most of the year.

Minnesota is called “The Land of Ten Thousand Lakes”, and there’s no doubt in my mind it’s true. Quite a change from here in the West. I believe California is named the Golden State not for the precious metal found here but rather for the color of the landscape during most of the year.

Another difference I noted on my trip westward was the number of NDBs. I counted 14 airports along the first portion of the leg with them. I think there are only 14 in all of California today. I was always a fan of NDB’s and still am when I venture to Alaska. Sadly, to me anyway, the NDB is going the way of the four-course range. I miss having an ADF and an RMI, but most new pilots have no idea what they are. They are “Children of the Magenta Line”.

The airplane cruised right along at about 120 knots and everything seemed to be fine. Just the same, I missed the JPI EDM930 in my Citabria. It gives me a wealth of information, not the least of which is EGT and CHT for each cylinder. I sure wished the Skylark had an EGT even if for only one cylinder. I kept my eye on the CHTs but the gauge was a funky device that showed the temps for two cylinders at a time with opposing needles. It had a knob type selector switch under the carb heat.

The airplane cruised right along at about 120 knots and everything seemed to be fine. Just the same, I missed the JPI EDM930 in my Citabria. It gives me a wealth of information, not the least of which is EGT and CHT for each cylinder. I sure wished the Skylark had an EGT even if for only one cylinder. I kept my eye on the CHTs but the gauge was a funky device that showed the temps for two cylinders at a time with opposing needles. It had a knob type selector switch under the carb heat.

Dale had said, you need to wiggle it to get it to work. Apparently wiggling is not in my skill set. It was useless to me. The oil pressure was in the green as was the oil temp but at the low end of the scale for each. I was not worried but something seemed to be not quite right.

Dale had said, you need to wiggle it to get it to work. Apparently wiggling is not in my skill set. It was useless to me. The oil pressure was in the green as was the oil temp but at the low end of the scale for each. I was not worried but something seemed to be not quite right.

After about three hours, I was coming up on Mobridge. I don’t know for sure but I’m guessing the town name was derived from the fact it is on the banks of the Missouri River and there is a bridge there. Just a guess mind you. It’s a small town with maybe 3000 people about 100 miles south of Bismarck, ND.

After about three hours, I was coming up on Mobridge. I don’t know for sure but I’m guessing the town name was derived from the fact it is on the banks of the Missouri River and there is a bridge there. Just a guess mind you. It’s a small town with maybe 3000 people about 100 miles south of Bismarck, ND.

I set up a downwind for runway 12 with a left pattern. I announced my position on the CTAF and made calls for each leg. I set it down just past the numbers and let it roll to the east end of the 4,400’ long runway.

As I shut down and climbed out, I didn’t see another airplane anywhere on the field. There was a large concrete ramp, a fuel island, what appeared to be a pilot lounge and a handful of hangars. I saw one car in the parking lot.

The pilot lounge was locked but someone was kind enough to leave the lock code on a note alongside the door. I smiled a bit remembering my mother use to put a key under the mat at the front door then leave a note telling any guests, invited or not, where it was. Midwest values and all that.

The pilot lounge was locked but someone was kind enough to leave the lock code on a note alongside the door. I smiled a bit remembering my mother use to put a key under the mat at the front door then leave a note telling any guests, invited or not, where it was. Midwest values and all that.

First things first, I needed the restroom. That taken care of, closing my flight plan, getting a weather update and filing my flight plan for the second leg were the next tasks.

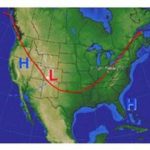

I called Flight Service and the briefer started with the synopsis and my, had things changed. She spent about 15 minutes on the phone with me providing a number options of which one was to return to Minneapolis. I told her I wanted to check in with some of the other aviation weather products available to pilots. Because it was getting messy, I wanted to see it. I’m a visual person and I’d prefer to look at charts and pictures to determine go/no-go and routing.

I logged into AviationWeather.gov, 1800wxbrief.com along with Foreflight. I checked the satellite, radar and surface analysis.

I checked the Airmets, Sigmets, CWA, UUA, Metars, TAFs, UA as well as winds aloft, icing and more. Everything indicated a change in plans was in order.

I checked the Airmets, Sigmets, CWA, UUA, Metars, TAFs, UA as well as winds aloft, icing and more. Everything indicated a change in plans was in order.

An area of low pressure was moving across the region to the southwest of me. Across Colorado, snow accumulations of 2-4 inches with locally higher amounts in excess of 5 inches were expected in the lower elevations. In the higher elevations, 4-8 inches with locally higher amounts in excess of 12 inches were forecast. In southeastern Wyoming, snow accumulations of 9-13 inches were expected with locally higher amounts in excess of 16 inches. In addition, winds of 20-30 mph with gusts in excess of 35 mph.

An area of low pressure was moving across the region to the southwest of me. Across Colorado, snow accumulations of 2-4 inches with locally higher amounts in excess of 5 inches were expected in the lower elevations. In the higher elevations, 4-8 inches with locally higher amounts in excess of 12 inches were forecast. In southeastern Wyoming, snow accumulations of 9-13 inches were expected with locally higher amounts in excess of 16 inches. In addition, winds of 20-30 mph with gusts in excess of 35 mph.

Any thoughts of heading south were dashed due to a strong line of thunderstorms producing tornadoes and straight-line wind stretching from the Central Plains to Nebraska.

Oh good grief. What happened to my weather window? I should have stayed in Minneapolis. The hotel had a nice bar.

I elected to head north toward Bismarck, ND then west to Billings, MT. I could not fly directly to Billings because the Powder River MOA was still forecast to be hot. Bismarck was reporting winds 095 @ 8 knots, vis 10, sky clear, temp 17, dewpoint 13, altimeter 30.24 hg and Billings current conditions were winds 210 @ 8, vis 10, 5k broken, temp 14, dewpoint 9, altimeter 29.88 hg. So that would be my new plan.

I would follow the Missouri River to Bismarck then westward to Billings. I would stay there for the night. As it happens, my mother lived in Billings so I just might have a place to stay and a home cooked meal.

Time out: I know what you’re thinking. How on earth do I remember all the weather information? I must be making this up. P-51 time as it were. Well, I wrote it down of course. I still have my notes from many of my extended flights. I never know when I might need to defend myself from those that think I’m full of chocolate pudding.

When I had parked the airplane upon arrival, I had swung the airplane around facing northeast. I’d exited the aircraft toward the tail and made a beeline for the pilot lounge to make a deposit in the coffee recycling room. The lounge was located on the passenger side of the aircraft and I had not looked at nor could I see the pilot’s side of the airplane while on the phone with flight service. At the self-serve fuel island, I slide my card, entered the appropriate data then grabbed the nozzle and ladder and walked to the pilot’s side of the airplane.

The side of the airplane was a lovely shade of brown. Mind you, that was not the color it was painted. The dark racing stripe started aft of the exhaust stack and flowed back toward the empennage. I set the ladder and fuel hose down and ran my finger across it. It appeared to be a combination of oil and exhaust. I opened the oil door on the cowl and made sure the oil cap was on then pulled the dipstick. It read 6 ½ quarts. The capacity was 10 and Dale had recommended filling it with 9 quarts for an extended flight. It lost 2 ½ quarts in three hours. Hmmm. I wonder if that was why there was half a case of oil in the baggage compartment along with those “extra” cylinders.

I pulled out the POH that Jim had graciously loaned me and looked for minimum oil level. I verified 5 quarts was the minimum as I thought. Why does it hold 10 if the minimum is 5 you ask? The FAA requires an engine be designed to hold twice as much oil as it actually needs. So, I figured the engine lost the oil through the breather.

I pulled out the POH that Jim had graciously loaned me and looked for minimum oil level. I verified 5 quarts was the minimum as I thought. Why does it hold 10 if the minimum is 5 you ask? The FAA requires an engine be designed to hold twice as much oil as it actually needs. So, I figured the engine lost the oil through the breather.

Nevertheless, I opened the pilot door and reached for my flight bag. I unzipped one of the smaller compartments and removed my St Joseph of Cupertino medallion and put it in my pocket. He’s the Patron Saint of Pilots. Although I’m not Catholic, I always figured I could use all the help I could. Being a saint, I didn’t think he’d mind if a Presbyterian looked to him for help. I went about fueling the airplane.

Nevertheless, I opened the pilot door and reached for my flight bag. I unzipped one of the smaller compartments and removed my St Joseph of Cupertino medallion and put it in my pocket. He’s the Patron Saint of Pilots. Although I’m not Catholic, I always figured I could use all the help I could. Being a saint, I didn’t think he’d mind if a Presbyterian looked to him for help. I went about fueling the airplane.

With it topped off, I went into the pilot lounge and reviewed my calculations for the new route. Finished, I called flight service and got yet another brief on the weather and filed my flight plan. I did a walk around and sumped the fuel drains, put on my survival vest, then climbed in. I fired it up and again it ran rough. I leaned it out quite a bit per my two other starts and announced on CTAF that I was back taxiing on the runway to the runup area of runway 12.

I turned the airplane’s nose into the wind and started going through my runup. I increased the mixture before running up the power to check the mags. The oil pressure was in the green but the oil temp was low. One of the issues with this airplane was the size of the oil cooler. I think it is sized large enough to cool the 9 liter Cummins diesel in my motorhome. The cooler was huge. Dale had covered ½ of it with metal tape. He said I might need to add more if it wouldn’t warm up. Silly me, I neglected to add duct tape to my tool kit.

Everything else seemed okay so I announced I was departing and lined up on the runway. I slowly added full throttle and off I went. It didn’t feel like the aircraft was accelerating the way it should. The RPM looked ok but none of the other gauges in the aircraft seemed to work. Why would I trust that one? I used an awful lot of the runway before I finally broke ground. The climb rate was not great, certainly not the way it should be with just me on board. I should be seeing 800-1000 fpm but the best I could manage was about 300.

I heard a Piper Arrow make a radio call reporting 10 miles out on a 45. I made a turn to the south to circle the town and follow the river. I was able to milk it to about 3,200 (1,500 AGL) by the time I was over the middle of the river. That’s when the shaking started. No, it was not “auto-rough.” Auto-rough is a phenomenon whereby an aircraft flying over-water or above mountainous terrain at night will begin to run rough. Coincidentally, the phenomenon also gives rise to a dramatic increase in a pilot’s hearing.

I pulled on the carb heat and leaned the mixture thinking maybe I’d picked up some carb ice and/or it was running too rich. That didn’t help. I pulled the power back to reduce the shaking and the engine stumbled. I added throttle and it meekly came back to life, but I was no longer able to hold altitude. I needed to get it back on the ground.

I was about 3 miles from the airport, 1,500’ above the Missouri River, losing altitude in an unfamiliar, rough running aircraft. Perfect. I heard the Arrow announce he was turning base and I keyed the mic and stated I had an emergency and needed to return. He said he would break off and get out of the way. The engine stumbled again. I shoved the throttle in all the way but it just seemed to make the shaking worse. I was now descending at about 400 fpm. I made a turn to make a 2-mile right base and grabbed the Johnson bar to add flaps 10. I reasoned the flaps would add more lift than drag. It took about a minute and a half to reach the extended centerline at about 300’ agl doing about 68 mph. It wasn’t until I was over the runway that I grabbed the Johnson Bar and pulled on full flaps. Touchdown!

They say any landing you can walk away from is a good landing. A landing where you get to use the airplane again is considered a great landing. It was not my best but at least the airplane can be used again.

I parked the airplane and walked to the pilot lounge. There was a small white board on the outside of the building that had the hand-written airport manager’s name and phone number. I got my cell phone out and dialed the number. Tyler answered the phone and I explained I needed some help at the airport. He said he was on the river fishing, but the bite was off and would be there in about half an hour.

I introduced myself when he arrived and I asked if he was an A&P. He said he wasn’t and further, that there was not an A&P in town. About that time, another gentleman (I don’t remember his name so I’ll call him Tom) arrived by car and walked over to us. He owned an Aeronca on the field but was not yet a licensed pilot. He offered that he had some tools if I needed. I told him I had some tools but if he had a borescope or a differential compression tester, I could use those. I said I’d like to remove the cowling, inspect the plugs and look inside the cylinders. He said he didn’t have either tool. Tyler said he would get a hold of a mechanic in Bismarck.

I removed the cowl and pulled the plugs. While they were not the worst I’d seen, they were fouled with lead and were wet. Tom had a plug cleaner like I use at home and I was able to clean the plugs. By the time I’d reinstalled and torqued the plugs, Tyler had reached a mechanic. I described what had happened and what I found. He said it sounded like a combination of the fouled plugs and the mixture set was too rich. Duh! He suggested when I start the engine to prime it then pull the mixture control to idle cut-off. When I crank the engine and it fires, let it smooth out and as it starts to die, then enrichen the mixture. Keep the mixture lean as I taxi and do my run up. If everything checks out, then do a full power lean as if I were making a high-density altitude departure.

I called Flight Service, got yet another weather update and opened my flight plan to Billings. I thanked Tyler and Tom and climbed aboard. The starting procedure was familiar to me as it was how I started my P210 years ago when the engine was hot. I fired up the 175 and back taxied to runway 12. I did a very thorough runup and then the full power leaning. It seemed to run okay. So, I announced I was departing and lined up.

I had calculated my takeoff distance to be about 800’. The runway aiming point markings are about 1,000’ down so I figured if I was not airborne by the time I passed the markings I would abort. I held the brakes and added full power. As I released the brakes and started down the runway, I began to pick up speed. Rolling. Rolling. Rolling. The markings passed but she was not ready to lift off. I closed the throttle and rolled to the end of the runway and taxied back to the ramp.

I climbed out of the aircraft as Tyler and Tom walked up. They had watched my attempted departure from the ramp and said the engine sounded weird. They believed it was a wise choice to abort. The engine had sounded okay to me. Then I realized I had turned on the ANR on my headset. I generally don’t do that before getting at least a 1,000 feet AGL for that very reason. I wear my headset with the right ear-cuff forward a bit so I hear the ambient noise when departing.

The wind was starting to stiffen so we walked toward the pilot lounge as a Navajo landed and taxied to the ramp. A nationally known parcel service truck arrived and pulled up next to it. The Navajo was operated by a contractor to the delivery company to provide service to outlying communities. Once a week, the Navajo arrived in Mobridge to drop off parcels. The pilot then waited around until late afternoon when the driver returned with outgoing parcels. The pilot assisted the driver to transfer boxes from the airplane into the brown truck. When finished, the driver drove off and the pilot joined us in the lounge.

I called Kevin to let him know there was a problem with the airplane and I was stuck in South Dakota. If I could get the airplane to Bismarck, the mechanic there can work on it but there was no way to get it there. I certainly wasn’t going to fly it. I wasn’t getting back in that airplane and that was fine with me. So here it stays and it’s Kevin’s and Dale’s problem. My problem now was how to get home.

There are no trains, planes or rental cars in Mobridge. I didn’t check for bus service. Tyler said he would drive me to Bismarck but he couldn’t go until Sunday (it’s Friday). From there I could catch an airline home. Well, that was not ideal but it was mighty generous to offer. I said that would be great and since it was getting near lunch I offered to buy.

Tyler, Tom and I went to a little café in town. It seemed as though everyone in the café knew each other. The waitress came over and handed me a menu – only me. Apparently, she already knew what the boys wanted. I glanced at the menu and ordered. I think we were in the café about an hour and in that time three different groups stopped at the table to say hi to Tyler, inquire about the fishing and to ask if I was the one with the broken airplane. Ya gotta love small towns.

We drove back to the airport and Tyler said he could store the airplane in a hangar until it could be repaired. He said it was not a good idea to leave it outside, especially with weather coming in. We pushed the airplane around to the hangar and secured it inside. I grabbed all my belongings and headed back to the pilot lounge. There, I called Kevin again and gave him the latest news.

The Navajo pilot had overheard us talking and when I hung up, he interjected. He could tell I was rather disappointed about not finishing the ferry flight and even more so due to having to stay in Mobridge a couple of days. He told me he was heading back to Sioux Falls late afternoon and if I wanted to ride along, I was welcome. Sioux Falls is served by United, American, Delta and others so getting home certainly was probable. I made it home the following day.

So what caused the problem with the engine? Kevin hired a mechanic, the same one that did the overhaul, to fly out to Mobridge to fix it. He found that 5 of the 6 exhaust values were sticking. Thank you, St. Joseph.